Product

News

- Soosan Hydraulic Breaker Price | High Cost-Effective SB Series Breaker Factory Direct Quotations!

- لماذا يفضل العملاء من الشرق الأوسط مطرقات فوروكاوا؟! نكشف أسباب شعبية سلسلتين HB و FX في السوق العربي

- Soosan Breaker Price Explained | Affordable SB81 Hydraulic Breaker with OEM Quality from China Manufacturer

- مصنع صيني متخصص في تصنيع مطارق التكسير Furukawa بنظام OEM | شريك موثوق لعملاء الشرق الأوسط

- Oferta Especial de Año Nuevo: Martillo Hidráulico Soosan SB81 Box Type Silenciado — Fabricación Completa en Zhengzhou Hanyun

- Soosan SB121 Hydraulic Breaker for Chile – Precision Manufacturing from a Full‑Chain Chinese Factory

contacts

Contacts:Jacky Zhang

Phone:+8618937103255

Email:hanyunpsq@gmail.com

Address:No. 167, Xuchang Road, Shangjie District, Zhengzhou City

Knowledge

Effective Methods for Resolving Hydraulic Breaker Chisel Fracture Issues

When using a hydraulic breaker, chisel fracture is a common issue, often caused by factors such as material quality, impurities, or internal defects. So how should we address these issues? Below, we will discuss how to effectively resolve chisel fracture problems.

The reasons for chisel breakage are not only related to the material quality of the chisel steel but also closely linked to factors such as erosion from mine water, heat treatment processes, and rock drilling techniques. During rock drilling, the chisel undergoes frequent impacts and twists of around 2000 times per minute, resulting in alternating pressure, tensile, bending, and shear stresses within the chisel.

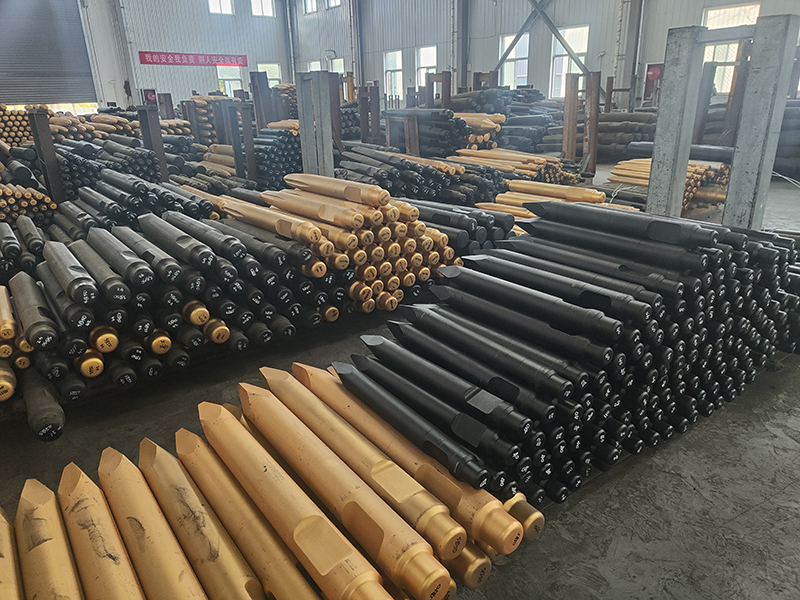

H-Wedge Chisel Tip breaker rod chisel

When these forces exceed the fatigue limit of the chisel steel, tiny cracks (fatigue cracks) form inside the chisel. As these cracks gradually enlarge, the effective cross-sectional area of the chisel decreases. Once the cross-section reduces to the point where it can no longer withstand impact loads or external forces, brittle failure occurs, leading to fatigue fracture. Hydraulic breaker manufacturers remind us that erosion from mine water and damp air can accelerate the expansion of cracks in the chisel steel.

Additionally, during the forging and heat treatment processes of the chisel tip, shoulder, and tail, improper temperature control or unreasonable processes can also result in the formation of thermal stress and microcracks within the chisel. Therefore, it is crucial to promptly address fracture issues using the methods mentioned above when using the chisel to minimize losses.

The above information covers the reasons and solutions for hydraulic breaker chisel fractures. It is hoped that through a detailed understanding of this product knowledge, users can operate and use the product more reasonably and effectively.