Product

News

- Soosan Hydraulic Breaker Price | High Cost-Effective SB Series Breaker Factory Direct Quotations!

- لماذا يفضل العملاء من الشرق الأوسط مطرقات فوروكاوا؟! نكشف أسباب شعبية سلسلتين HB و FX في السوق العربي

- Soosan Breaker Price Explained | Affordable SB81 Hydraulic Breaker with OEM Quality from China Manufacturer

- مصنع صيني متخصص في تصنيع مطارق التكسير Furukawa بنظام OEM | شريك موثوق لعملاء الشرق الأوسط

- Oferta Especial de Año Nuevo: Martillo Hidráulico Soosan SB81 Box Type Silenciado — Fabricación Completa en Zhengzhou Hanyun

- Soosan SB121 Hydraulic Breaker for Chile – Precision Manufacturing from a Full‑Chain Chinese Factory

contacts

Contacts:Jacky Zhang

Phone:+8618937103255

Email:hanyunpsq@gmail.com

Address:No. 167, Xuchang Road, Shangjie District, Zhengzhou City

Knowledge

Hydraulic Breaker Black Oil: What to Do? Manufacturer Explains Causes & Solutions!

I. Common Causes of Black Oil in Hydraulic Breakers

1. Dust Infiltration into the Hydraulic System

2. Improper Grease Lubrication

3. Lack of Filtration in the Return Oil System

4. Excessive Wear of Upper & Lower Bushings

5. Damaged or Clogged Intake Check Valve

6. Mismatched Chisel and Bushing

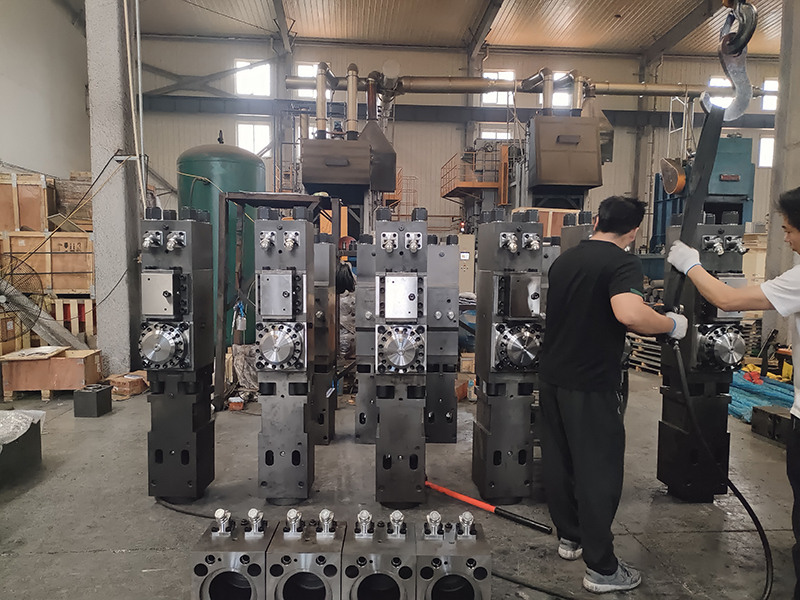

Zhengzhou Hanyun Hydraulic Breaker — Furukawa HB30G Assembly Precision & Special Offer for Egypt Customer

II. Practical Solutions for Black Oil (Manufacturer’s Recommendations)

✅ 1. Replace Dust Seals in a Timely Manner

Aged or damaged dust seals are the main channel for dust infiltration. Inspect and replace dust seals regularly, and avoid frequent eccentric striking to reduce seal wear.

✅ 2. Install Return Oil Filters and Water Spraying Devices

Return oil filters can effectively intercept impurities in the hydraulic fluid, while water spraying devices suppress dust diffusion at the work site—both are key measures to prevent black oil formation.

✅ 3. Regularly Inspect and Replace Upper & Lower Bushings

Replace the bushings promptly when their wear exceeds the tolerance standard, to ensure the stable operation of the chisel and minimize impurity infiltration.

✅ 4. Refuel Grease in the Correct Way

Lift the hydraulic breaker vertically and fully press the chisel into the piston chamber before greasing. Add only half a standard grease gun’s worth of grease each time to avoid overfilling and grease infiltration into the hydraulic chamber.

✅ 5. Clean the Intake Check Valve Regularly

Inspect the intake check valve for clogging or damage, and maintain the normal operation of the nitrogen system to prevent uneven air-liquid mixing and abnormal oil flow.

✅ 6. Check the Fit Precision of Chisel and Bushing

Use chisels that match the model of the hydraulic breaker to avoid additional wear and hydraulic fluid contamination caused by mismatched dimensions.