Product

News

- Soosan Hydraulic Breaker Price | High Cost-Effective SB Series Breaker Factory Direct Quotations!

- لماذا يفضل العملاء من الشرق الأوسط مطرقات فوروكاوا؟! نكشف أسباب شعبية سلسلتين HB و FX في السوق العربي

- Soosan Breaker Price Explained | Affordable SB81 Hydraulic Breaker with OEM Quality from China Manufacturer

- مصنع صيني متخصص في تصنيع مطارق التكسير Furukawa بنظام OEM | شريك موثوق لعملاء الشرق الأوسط

- Oferta Especial de Año Nuevo: Martillo Hidráulico Soosan SB81 Box Type Silenciado — Fabricación Completa en Zhengzhou Hanyun

- Soosan SB121 Hydraulic Breaker for Chile – Precision Manufacturing from a Full‑Chain Chinese Factory

contacts

Contacts:Jacky Zhang

Phone:+8618937103255

Email:hanyunpsq@gmail.com

Address:No. 167, Xuchang Road, Shangjie District, Zhengzhou City

Knowledge

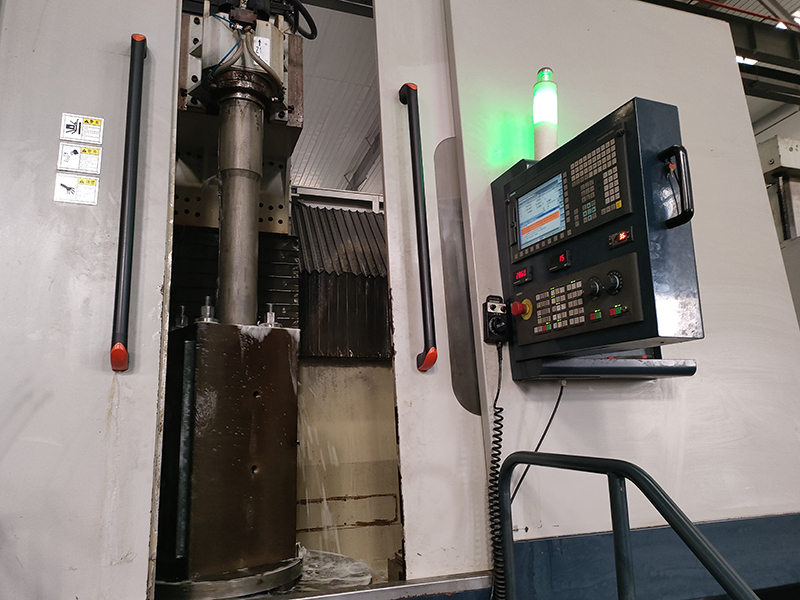

Why Choose Vertical Grinders for Hydraulic Breaker Cylinder Machining? Zhengzhou Hanyun Breaks Down Their Advantages!

Release time:2026年1月27日

In the production of hydraulic breakers, the machining precision of cylinders plays a decisive role in the overall performance of the complete equipment. As the core channel for the reciprocating movement of pistons, cylinders have extremely high requirements for coaxiality, roundness and surface finish. Even a slight deviation will not only reduce the impact force, but also lead to problems such as piston jamming and seal failure.

As a professional manufacturer with a complete industrial chain for hydraulic breakers, Zhengzhou Hanyun adheres to high standards and high precision in the cylinder machining process. We adopt high-precision vertical grinders, which have significant technical advantages compared with traditional horizontal grinders.

So what are the specific advantages of vertical grinders over horizontal grinders for hydraulic breaker cylinder machining?

Why Choose Vertical Grinders for Hydraulic Breaker Cylinder Machining Zhengzhou Hanyun Breaks Down Their Advantages!

✅ Core Advantages of Vertical Grinders

Higher Machining Precision

Vertical grinders feature superior gravity centering control. Workpieces maintain stable self-weight in the vertical direction and are less prone to deflection, effectively improving the coaxiality and roundness precision of hydraulic breaker cylinders.

Ideal for Large Cylinder Machining

The middle and lower cylinders of hydraulic breakers are mostly of large-diameter and deep-hole structures. Vertical grinders enable better clamping and positioning of workpieces, ensuring strong machining stability during the production process.

Reduced Impact of Thermal Deformation

Horizontal grinders with horizontal spindle arrangement are more likely to generate thermal deformation during high-speed operation, which impairs machining precision. In contrast, the vertical structure facilitates natural heat dissipation, ensuring consistent machining dimensions of cylinders.

Higher Machining Efficiency

Vertical grinders have a shorter grinding path and higher cutting efficiency. Meanwhile, they reduce tool change and clamping time, significantly boosting the overall production capacity of hydraulic breaker cylinders.

Better Operational Safety

Workpieces placed vertically are more stable, which reduces the risks of vibration and displacement during machining and greatly improves the operational safety of the production line.

At Zhengzhou Hanyun’s hydraulic breaker production plant, vertical grinders are just one part of our advanced equipment lineup. We are also equipped with a full set of world-class processing and manufacturing equipment, including:

- Korean Doosan Machining Centers

- Austrian Aichelin Heat Treatment Furnaces

- Japanese CNC Grinding Machines

- -190°C Cryogenic Treatment Equipment

- Taiwanese Deep-Hole Drilling Equipment

We insist on the independent production of all core components of hydraulic breakers, including cylinders, outer shells, pistons, bushings, flat pins and chisels. Realizing integrated production from raw materials to finished products, we strongly guarantee the quality, performance and stability of every hydraulic breaker product.

#HydraulicBreakerCylinderMachining #VerticalGrinderAdvantages #HydraulicBreakerManufacturing #HighPrecisionMachining

上一篇:Why Do box type silenced hydraulic breaker Adopt Extended Outer Bushings? Professional Answers from Zhengzhou Hanyun!

下一篇: Hydraulic Breaker Cylinder Oil Leakage: Common Causes & Complete Solutions | Seal Failure, Component Wear, Assembly Issues Explained